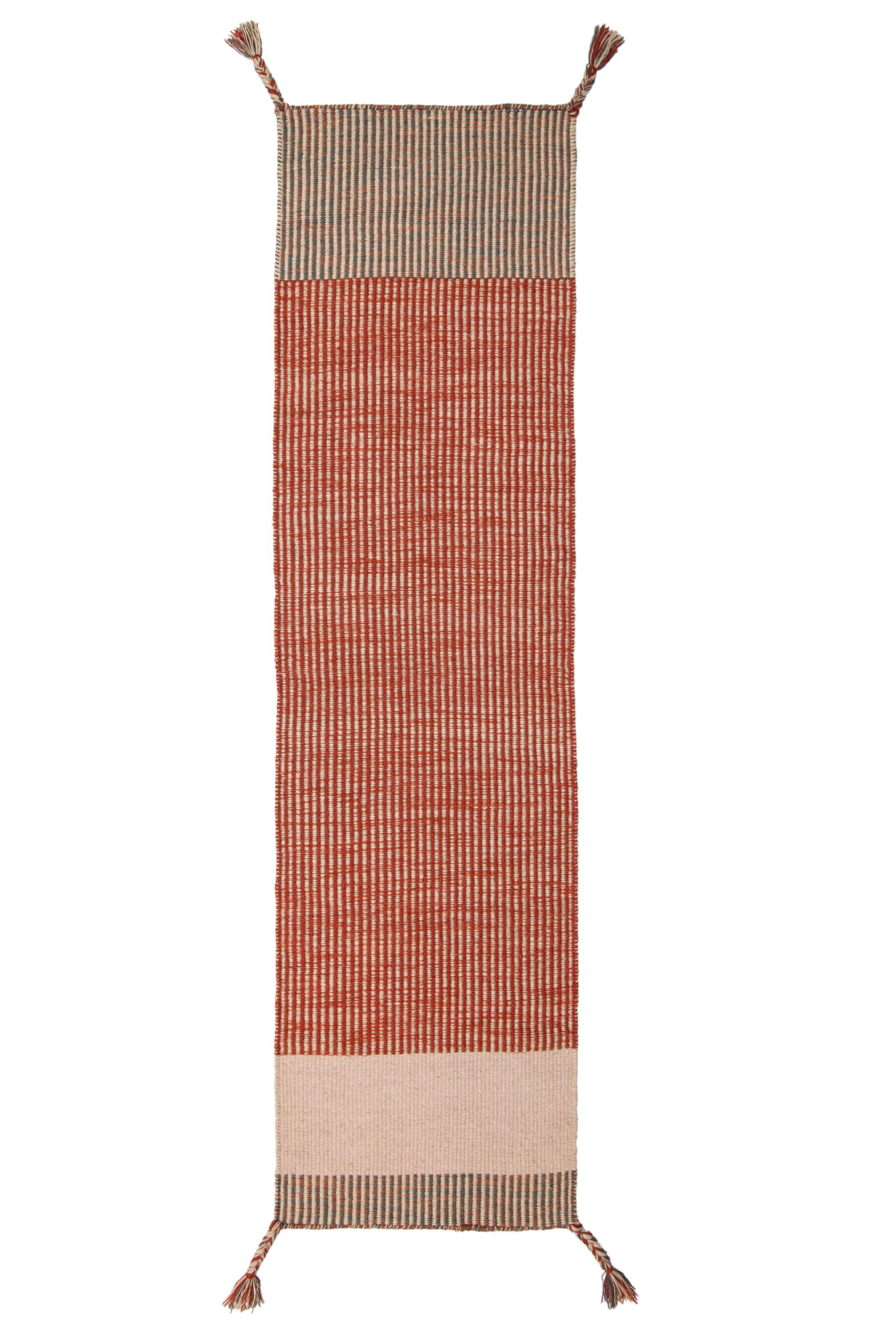

Woven with love

Here at Flair, our international family includes some of the best craftspeople from across the world, and partnerships that we’ve nurtured over many years.

Skilled artisans and generations of experience help to create beautiful centrepieces for people’s homes, and we are excited to tell you all about it.

1. Sorting

Raw materials like wool, jute, cotton and more, which come in a spectrum of colours, are sorted, and reviewed to guarantee the highest quality materials are chosen.

2. Spinning

To turn these raw materials into twisted loose yarn bundles called ‘skeins,’ a range of spinning methods are used. Now they are ready for dipping.

3. Dipping

The ‘skeins’ or bundles of yarn are repeatedly dipped into sizable colour tubs to ensure that they are thoroughly dyed by all the natural pigments in the containers.

4. Dyeing

Because of the complex nature of colour and its need for complete accuracy, this process of dying is overseen by expert artisans to ensure that the desired colour shade is met. Once they are happy with the colour, the yard is washed again to set.

5. Drying

To further capture the enriching colours of the yarns, they are then left out in the sun to dry naturally.

6. Weaving

This method of weaving by hand is a treasured skill and tradition, having been passed down by generations for centuries, while continuously maintaining an excellent standard in execution and quality.

7. Finishing

To further lock in the vibrant colours and retain its shape, the rug is then lightly washed. Here is where the minute details come to fruition. The rugs are reviewed, loose ends are trimmed, and time is taken to ensure that everyone is happy with the product.

8. To your home

For us, this story only ends when our rugs become a cherished part of a home as something enjoyed for its craftsmanship, beauty and quality; having made the journey through these steps, all the way to your living space.